Fundamental study of commercial polylactic acid and coconut fiber

€ 21.50 · 5 (403) · In Magazzino

This study aims to provide an alternative fully green biodegradable<?index value="biodegradable"?> 3D printing<?index value="3D printing"?> filament<?index value="3D printing filament"?> other than polylactic acid (PLA)<?index value="Polylactic Acid (PLA)"?> with better properties and lower prices using a fully environmentally friendly process. Two filaments [polylactic acid (PLA) and polylactic acid/coconut fiber (PLA-CF)<?index value="Polylactic Acid/Coconut fiber (PLA-CF)"?>] to be purchased and used to prepare a similar samples under the same conditions which to undergo the same testing to obtain and compare their properties as well as for further comparison with other filaments. The samples are to be designed using SOLIDWORKS<?index value="SOLIDWORKS"?> software according to the American Society for Testing and Materials (ASTM)<?index value="American Society for Testing and Materials (ASTM)"?>standards. The prepared designs are then to be converted to gcode using CURA software. FDM Creality 3D printer (Model: CR10S-PRO) to be used printing a set of specimens for each required test. The prepared samples then undergo several mechanical tests to specify their exact properties. PLA 3D filament<?index value="filament"?> roll had been purchased from Fabbxible Technology; Crystallized nature based NatureWorks made from corn starch. While Magma PLA-CF roll had been purchased from 3D Gadgets Malaysia. Both rolls had an average diameter of 1.75 mm and average length of 300 m.

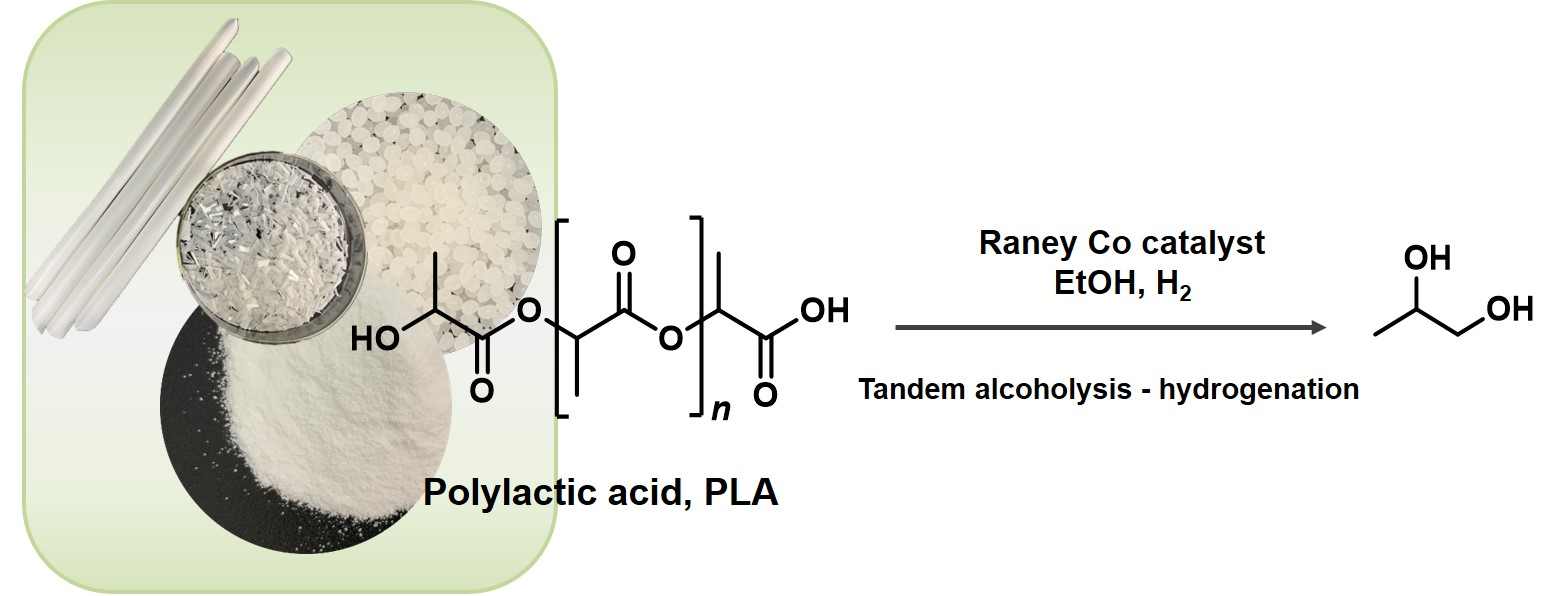

Proposed schematic mechanism of PLA biodegradation. PLA: poly(lactic acid).

Proposed retting and extraction mechanisms of coir fibers from coconut

Photographs showing the physical and morphological structure of coconut

Composition of poly (lactic acid) (PLA) and poly (butylene

Polymers, Free Full-Text

Polymers, Free Full-Text

PDF) Polylactic Acid (PLA) Biocomposite: Processing, Additive Manufacturing and Advanced Applications

Polylactic acid (PLA) biocomposites reinforced with coir fibres: Evaluation of mechanical performance and multifunctional properties - ScienceDirect

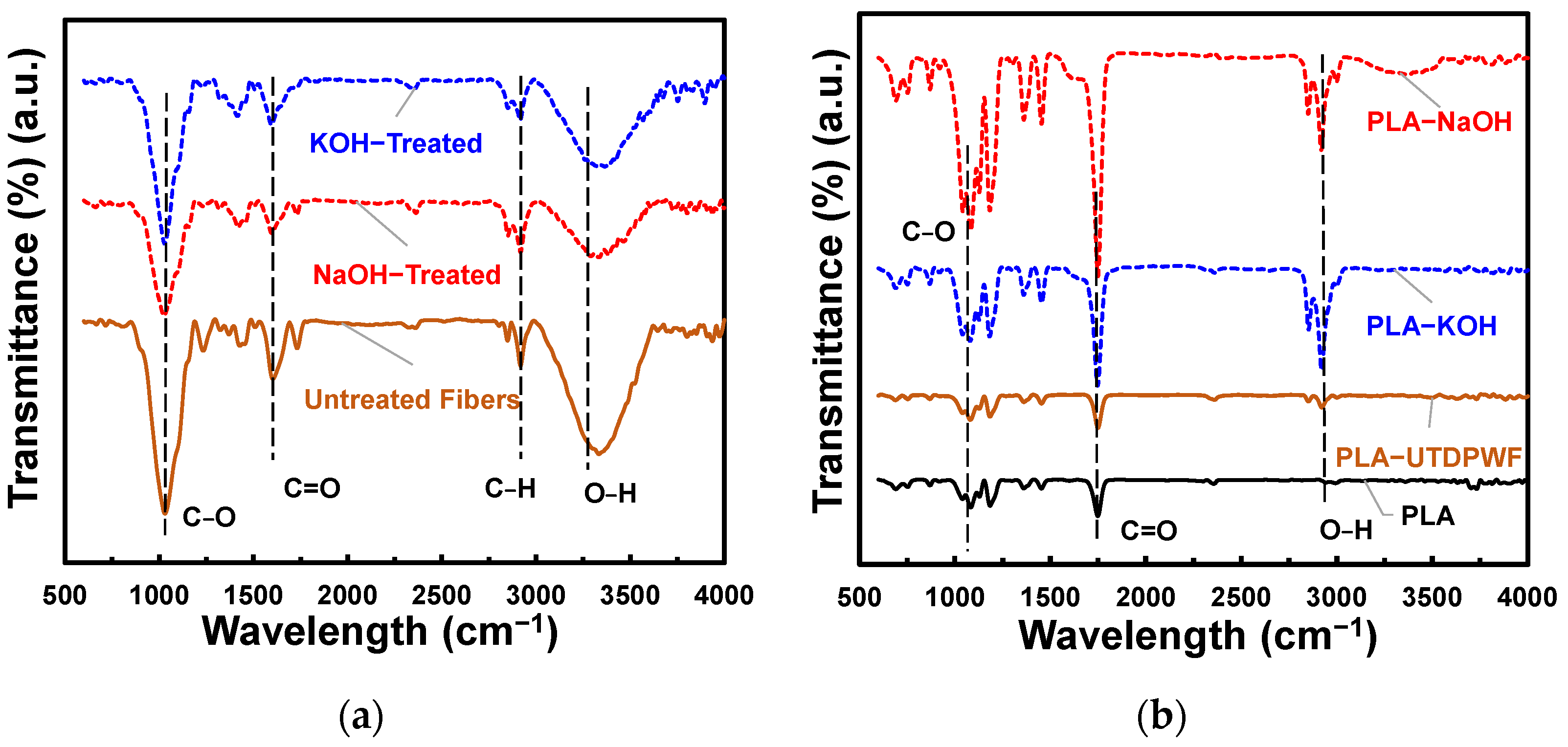

Surface modification of coconut shell powder filled polylactic acid biocomposites - H Salmah, SC Koay, O Hakimah, 2013

Polymers, Free Full-Text

Polylactic acid (PLA) 【Physical】What are the modification methods?

PLA based biocomposites for sustainable products: A review - ScienceDirect

Polymers, Free Full-Text

Eco-efficiency of poly (lactic acid)-Starch-Cotton composite with high natural cotton fiber content: Environmental and functional value - ScienceDirect

Flexural properties of the PLA/coconut coir composites: (a) flexural